Mattingly Lumber: Technically Sound

November 9, 2023

For lumberyards that have — or want — a strong component framing operation, success comes from creating exceptional value for their customers.

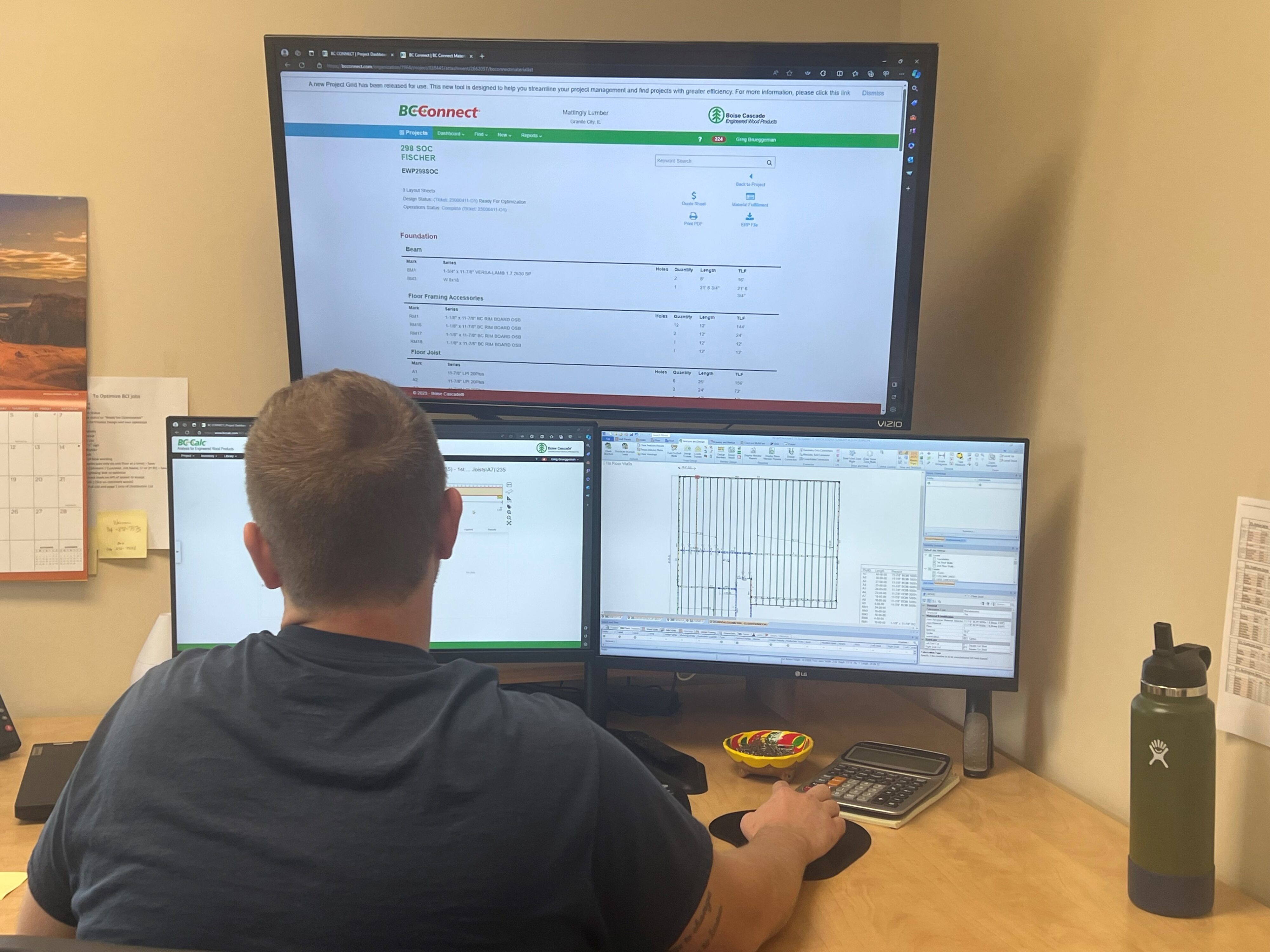

Mattingly Lumber in Granite City, Illinois has achieved increased success by boosting efficiency for both their customers and their own operation by implementing technology, including Boise Cascade’s BC Connect®, BC Calc®, and their SawTek® automated saw system.

Located just across the Mississippi River from St. Louis, Mattingly Lumber was founded by lumber industry veteran John Mattingly, Sr. more than 30 years ago. Today, the company is run by his son John Mattingly, Jr. and provides not just lumber, but turn-key building solutions, including handling the design and build of roof trusses, floor systems, wall panels, and more.

Mattingly Lumber designer Greg Brueggeman says he uses Boise Cascade technology nearly every day to reduce waste and increase efficiency in both EWP processing at his facility and installation time on the job site. He uses BC Calc to size joists and beams and evaluate job site repair conditions, BC Connect to manage project files and optimize material lists against available inventory, and the SawTek saw system to cut and label field-ready job packs.

“It’s very user-friendly,” Brueggeman says. “As far as some of the programs we use, they’re pretty far ahead of the competitors as far as design software.”

Getting Answers with BC Calc

As everybody knows, building a strong, safe structure is at the core of a designer’s job. But building strong and safe isn’t enough for true professionals — they also have to build smart.

Brueggeman and his team use BC Calc to help them understand the implications of various design choices on both performance and the budget.

“If I have any questionable areas, I will send it to the BC Calc program,” Brueggeman says. “I’ll use it quite often for new master plans because I want to make sure I’m meeting the builder’s specs.”

But the biggest impact BC Calc has made for the Mattingly team is how it improves communication.

“It’s probably helped me the most with being able to create reports that are easily viewed by another architect or builder or a carpenter,” he says, explaining that BC Calc’s reports mean he can quickly and easily point out potential trouble areas and explain how they can be rectified.

Staying Connected with BC Connect

To organize the large amount of information, from layouts to analysis to schedules, that every project generates, Mattingly Lumber relies on BC Connect. BC Connect provides a single source of customer and project information that can be shared between the design and operations teams while also providing critical updates to the sales team.

“A nice part is that it’s all cloud-based,” Brueggeman says. “Your layouts are in the cloud and it allows access to those layouts in the field or if your salesperson is in the field. You have the option to access it pretty much anywhere.”

Just as importantly, having a “single source of truth” that integrates with other popular software programs helps the Mattingly team reduce the chance for human error.

“I like the fact that when my layout program is connected to BC Connect, if I make a change to my layout, it changes the file in BC Connect automatically,” Brueggeman says. “I don’t have to worry if I uploaded the right file.”

But all the technology in the world is only useful if it gets used. And that, Brueggeman explains, is what really makes BC Connect work. “It’s user-friendly for me, for my yard guys, and my customers,” he says. “It encompasses a lot of what you want your program to be able to achieve for you.”

Bringing it Together with SawTek

Eventually, layouts have to leave the computer and enter the real world. That’s where the SawTek automated saw system comes in. “The old way we used to do it, I’d do a layout and give it to our guy in the yard and he would basically create a cut list on his own,” says Brueggeman.

Now, with the help of SawTek, Mattingly can deliver pre-cut and labeled job packs that only need to be trimmed. “That helps eliminate waste in the field and helps eliminate waste in our yard,” he says.

This also has a not-so-obvious benefit of helping the Mattingly Lumber team make better purchasing decisions. “It helps allow us to have smaller inventory in terms of not having to carry all these lengths, and maximize the usability of your lineal footage,” Brueggeman says.

The greatest benefit SawTek and its integrated software bring, according to Brueggeman, isn’t at the yard, it’s in the field.

“The biggest thing is probably the time in the field for the framers,” he explains. “They basically have a layout that’s labeled A1, A2, A3. And we deliver a stack of BCI joists labeled A1, A2, A3. It tells framers where each needs to go without having to guess. It cuts down on waste on our end and we’ve been able to use it as a very big selling point to the builders in the area.”

Brueggeman tells the story of a customer who decided to split some of their business between Mattingly and another lumberyard that didn’t use Boise Cascade technology in hopes of increasing their throughput.

“That went on for a little while, but then the builder’s main office started hearing from carpenters saying this is costing us time — it’s not the same way as Mattingly does it,” he says with a smile.

Weeks later, that homebuilder brought its business back to Mattingly Lumber.

For Brueggeman and the rest of the Mattingly team, technology is just another tool to deliver the best possible experience to customers while building a strong business of their own.

“I’d say right now it’s doing exactly what we need it to do.”