McCray Lumber – Big Math in Small Numbers

December 4, 2024

A Long Legacy Built in the Midwest

For more than 75 years, McCray Lumber and Millwork has served as a building material dealer to customers in Kansas City, Topeka, and Lawrence, Kansas. They proudly carry the highest caliber of products, while operating with 50 acres of open yard, over half a million square feet of covered storage, and 100 trucks.

McCray’s customer-centric mission and eagerness to embrace new technology — a philosophy the team describes as staying on the “leading edge” — has benefited them year after year. The company has successfully weathered economic downturns with tenacity and resilience and given them an outstanding reputation that has endured generations. With a history like theirs, McCray’s partnership with another long-established industry leader like Boise Cascade® was an obvious fit.

A Challenge for the Ages

In recent years, McCray Lumber recognized an opportunity to better address challenges in the Kansas City market, which is known for using 2×10 solid sawn lumber for floor systems in new construction. While preferred for its low cost, this option can present problems for builders — such as warranty callbacks due to twisting, shrinking, and bowing of newly installed flooring.

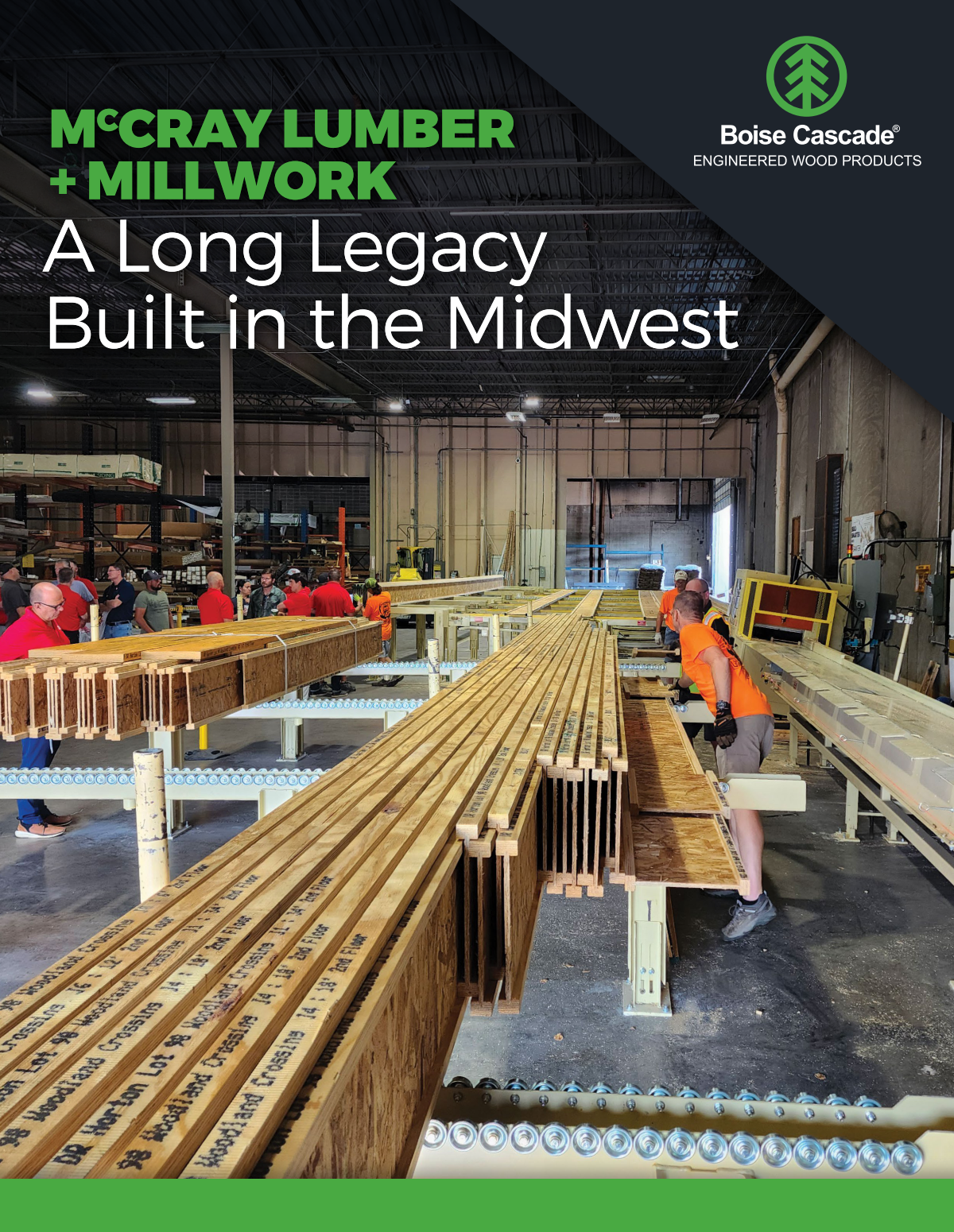

As a true leader, McCray was ready to introduce an improved way to build and wanted to help their customers be more successful. Enter: Boise Cascade’s SawTek® automated saw system, which McCray began using in the summer of 2024.

This comprehensive solution, combined with the use of BCI® joists, seamlessly integrates advanced software with a state-of-the-art saw, providing automated processing for engineered wood products (EWP). The SawTek system allows dealers like McCray to utilize the latest technology to cut floor components directly from plans, using only the materials needed.

The result? Pre-cut, pre-packaged, and clearly labeled connections on the framing materials — known as job packs — are provided for each job site. Job packs are created when the team transfers the cut data to the SawTek system and then feeds the specified BCI joists onto the in-feed table. The system goes to work, cutting the BCI joists precisely to length while routing holes for mechanicals — a distinct advantage over traditional 2×10 solid sawn lumber.

Building Smarter with the SawTek System and Compatible BCI Joists

This automated approach is a win-win for McCray Lumber and builders. Believing “there is big math in small numbers,” their implementation of SawTek’s innovative system helped increase efficiency, optimize their inventory, and reduce waste, which results in savings for both them and customers.

“We can already see efficiencies,” said McCray Lumber COO Gene Bosley. “And little things add up quickly, particularly if you’ve got some scale — if you’re at 225 employees and doing the business we do, a couple of basis points in savings make a difference.”

The SawTek system also benefits cost-conscious, deadline-oriented builders by maximizing their material, time, and budget. Each job pack comes complete with an install guide, black-and-white and color layouts, and clearly labeled floor packages including BCI joists, Versa-Lam LVL beams and rim board, complete with pre-cut holes and precision cuts. This meticulous organization reduces confusion and costly framing errors, decreases installation time, and reduces on-site cutting and waste. Builders, in turn, greatly improve their efficiency on construction sites.

Not only are these pre-cut job packs quicker and easier to install, but builders also see improved performance of BCI joists over 2×10 solid sawn lumber. Including:

-Precision: BCI joists can be cut to exact lengths

-Consistency: BCI joists don’t shrink, twist, or bow

-Strength: BCI joists are up to 20 percent stronger than comparably sized dimensional lumber

-Length: BCI joists can span greater distances without warping

-Resource Efficiency: BCI joists use less wood fiber than solid sawn lumber, making them a more sustainable option

Reinforcing a Future of Excellence

McCray continues to thrive today, thanks to advanced technology, optimized processes, and superior products. Implementing the SawTek automated saw system has allowed them to showcase the superior performance of BCI joists compared to traditional 2×10 solid sawn lumber, solidifying their position as a forward-thinking leader in the building materials market.

By providing solutions that address the real-world challenges builders face — from labor shortages to project timelines — McCray has positioned itself as not just a supplier, but a valuable and trusted partner in the construction process.

Looking for a printed copy? Download it here!