What Are I-Joists?

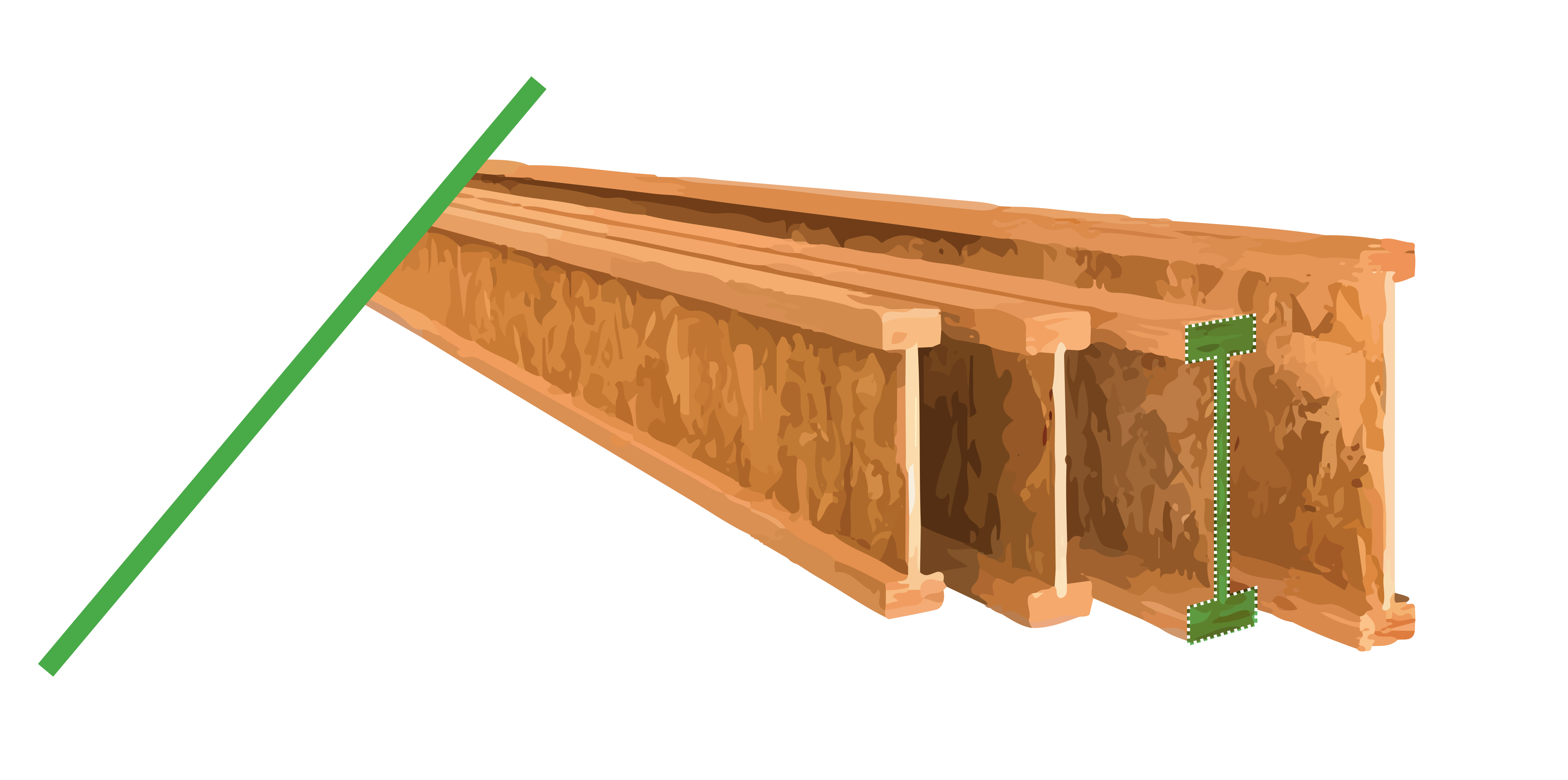

I-joists are structural engineered wood products used for framing floors and roofs. The consistency allows for solid performance, flat floors, and smooth ceilings.

Like all floor joists, I-joists are typically used to transfer loads to beams, walls, and the foundation. Unlike traditional dimension lumber, which can twist, split, and bow, BCI® joists offer better consistency and strength while weighing less and being easier to handle. These attributes make I-joists popular with builders of single-family homes, as well as light commercial and multi-family structures.

What Are the Benefits of I-Joists?

I-joists have become a construction industry standard largely because they offer reliable strength, consistency, and engineered performance that can provide better value than other floor framing options. But that’s just the start of their benefits.

Strength: Thanks to their unique construction, BCI joists are up to 20 percent stronger than comparably sized dimension lumber.

Long Lengths: BCI joists are manufactured in long lengths and can be used to create open floor plans, which can be installed faster and offer flexibility in design.

Easier Handling: Open-Web Floor Trusses (OWFT) and dimensional lumber can be heavy and difficult to handle, but BCI joists are lightweight, helping reduce labor hours and labor costs.

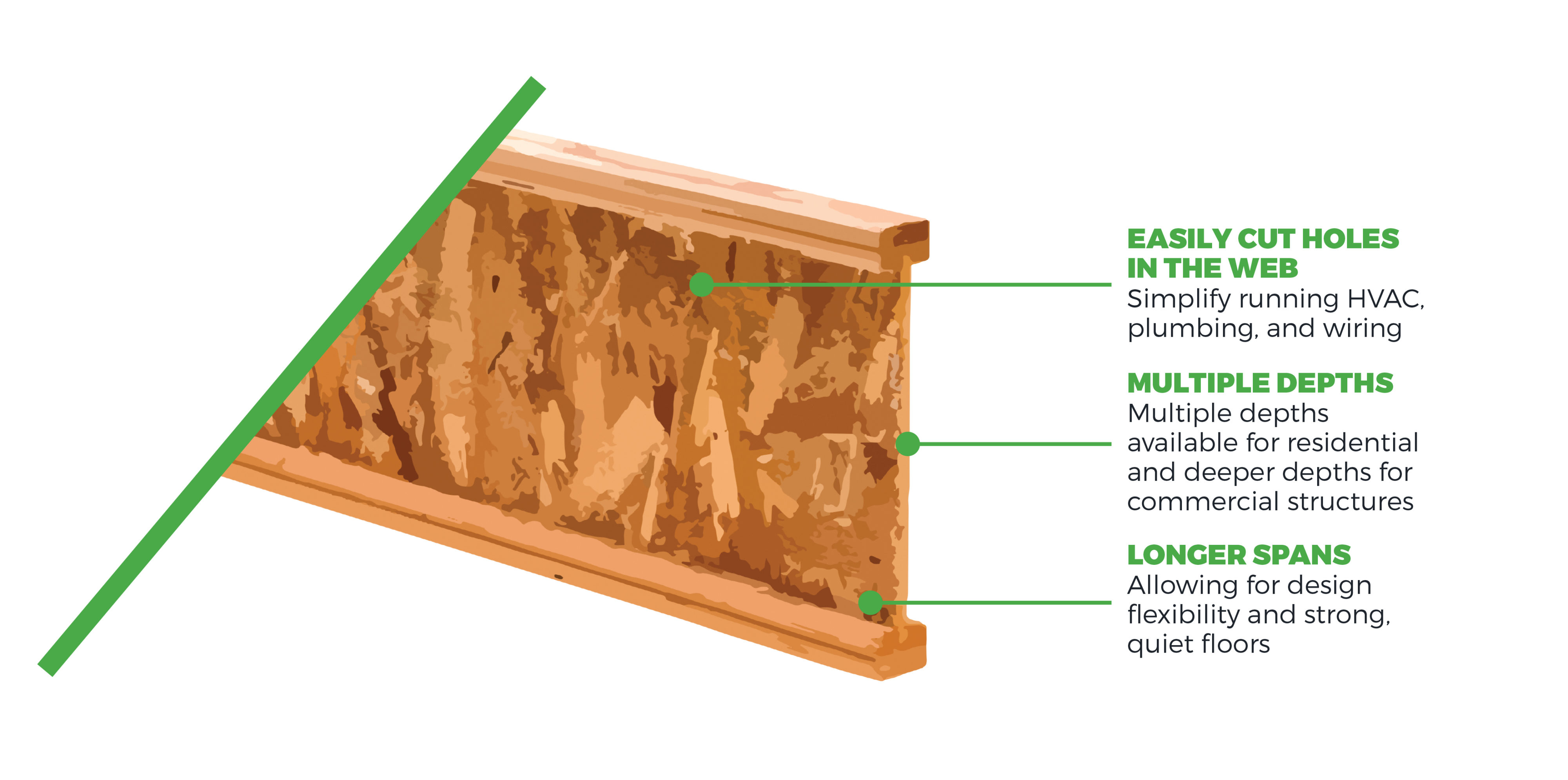

Adaptable on the Jobsite: BCI joists can be quickly trimmed in the field. They also come with pre-stamped knockouts for wires and allow for large holes to be cut out of the web for mechanicals and HVAC, while still performing and meeting load requirements. OWFT are custom-built for each job, and any on-site modifications can be difficult, time-consuming, and may require the trusses to be rebuilt.

Always Consistent: I-joists are engineered and manufactured for reliability — you’ll receive the same carefully made, consistently performing, and professionally inspected product time after time.

Sustainably Made: A typical I-joist uses only about half the wood of dimension lumber. The raw materials used in the manufacture of BCI and AJS I-joists are sourced from sustainable and responsibly managed forests. Boise Cascade strives to maximize the use and minimize the waste of each log procured. Bark and material residuals are used for carbon-neutral biomass fuel to generate over 70% of the energy needed to manufacture our products, keeping our emissions and reliance on fossil fuels low.

What Is an I-Joist Used For?

I-joists are a go-to product for residential and multi-family construction projects because they’re available in common sizes for today’s construction projects. They can also reduce common mistakes and hassles to make: framing simpler, floors flatter, and homes perform to meet customer expectations.

The strength and stability of I-joists make them a popular choice for engineered floors and roof framing. I-joists come in longer spans than dimensional lumber but without the potential defects and imperfections that eat up time and labor at the job site. With less shrinking, twisting, and bowing, the result is simpler floor and roof layouts that perform over time. Their consistency and performance, along with proper design, helps reduce vibrations, which means less bounce, fewer squeaks, and solid, quiet floors.

How Are I-Joists Made?

I-joists consist of OSB web between two flanges, which are typically constructed of dimensional lumber or laminated veneer lumber (LVL) and joined by a durable structural adhesive. BCI® Joists use Versa-Lam® LVL for strength and durability while AJS joists have flanges made of machine stress-rated lumber.

A finished I-joist looks like the letter I, lending the product its name.

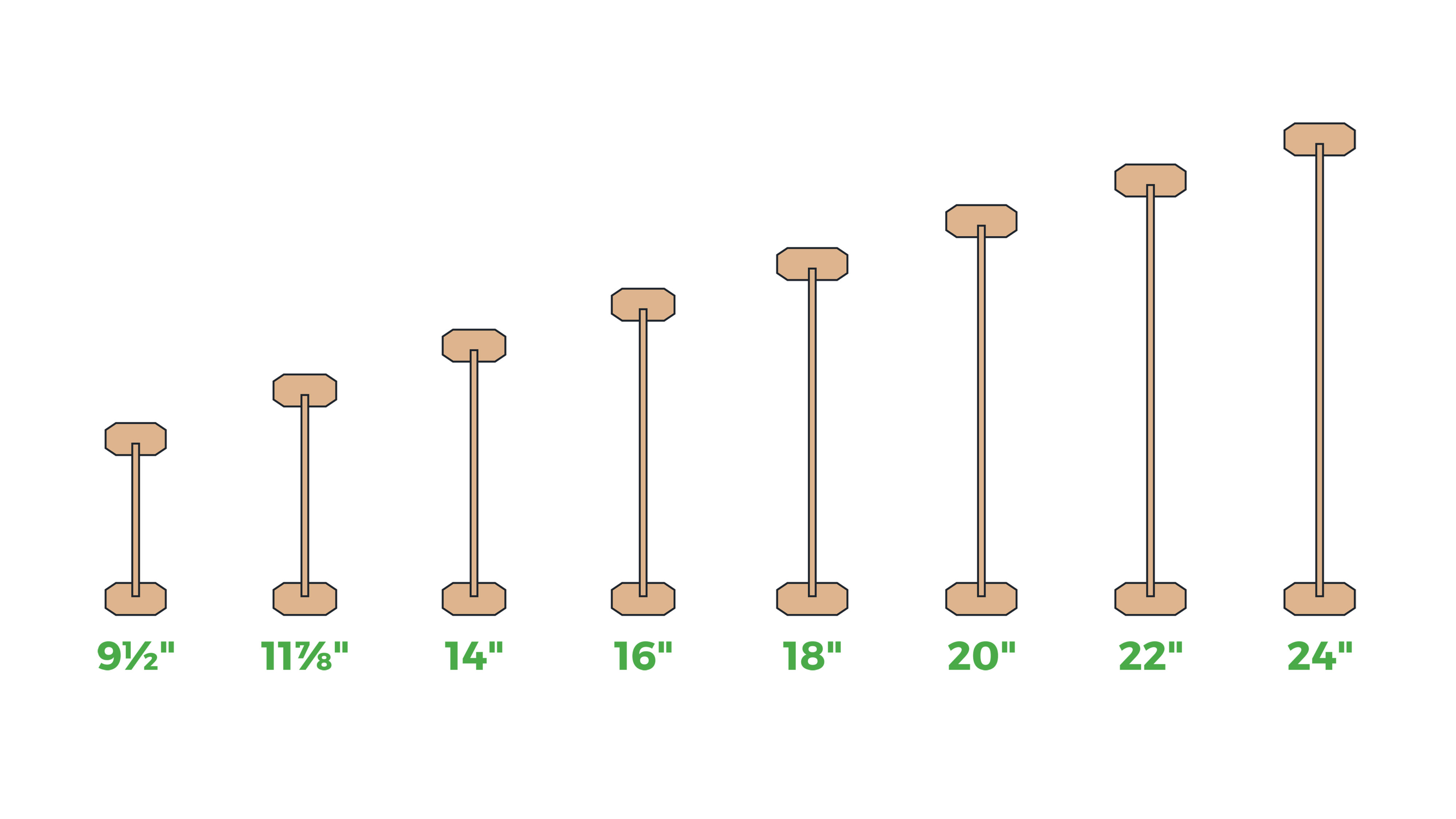

What Are Common I-Joists Sizes?

I-Joists are manufactured in a wide range of depths ranging from 9 ½″-24″ and can be special ordered in lengths as long as 60 feet.

BCI Joists are available in standard depths up to 20″ and AJS joists are available in depths up to 24″. The extra depths make an ideal solution for multifamily applications.

How Far Do I-Joists Span?

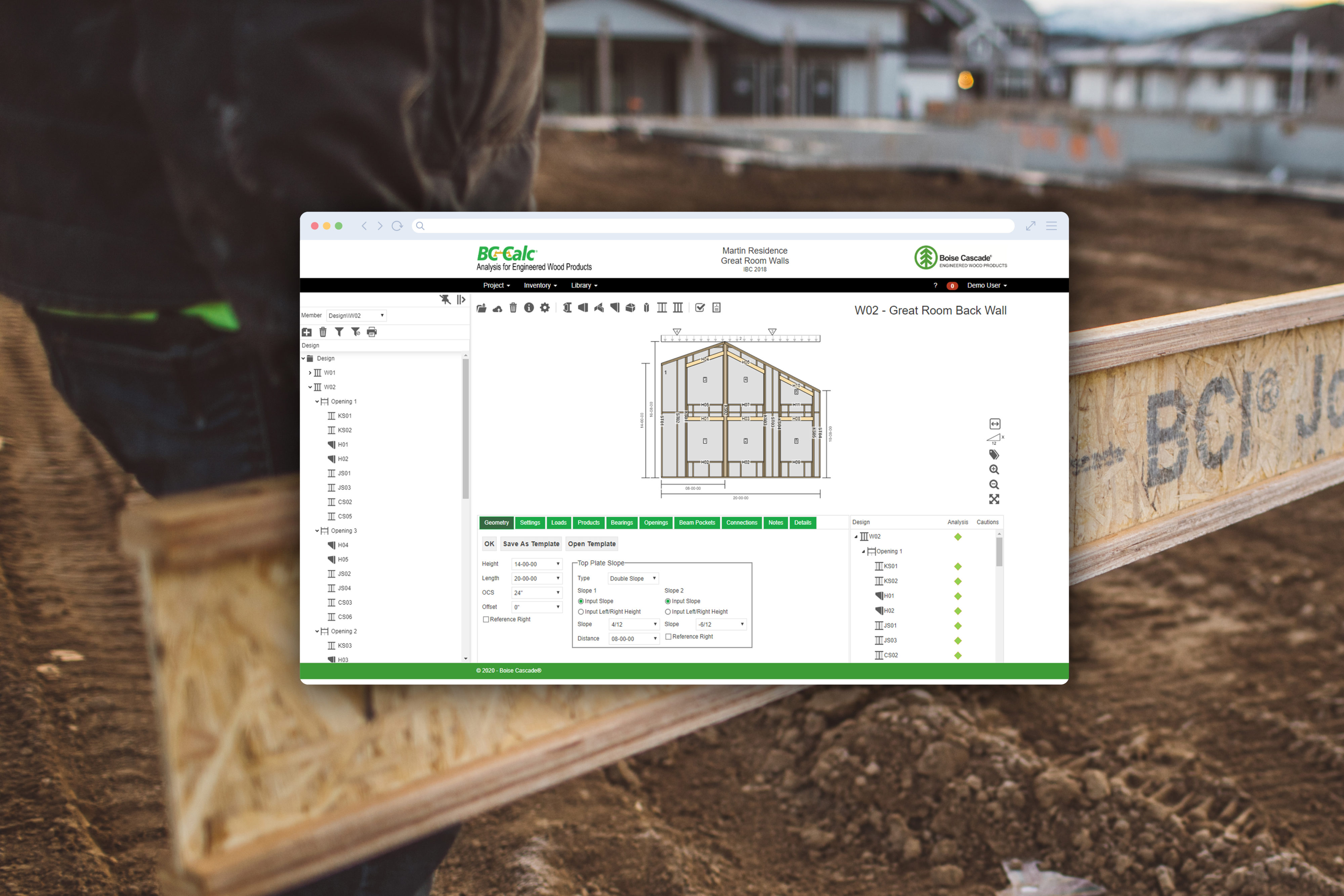

The answer to this question depends on many factors unique to your project. Download the BCI or AJS I-joist Specifier’s guide to see I-joist span chart for your specific application or learn more about the Boise Cascade software suite.