Become the EWP supplier home builders trust to supply, cut, and deliver right — every time.

SawTek

Saw System

Revolutionize your engineered wood business with the industry's leading automated saw system.

-

For Dealers

-

For Builders

Discover the benefits of an EWP supplier who uses SawTek® to make your job faster, stronger, and easier.

Dealers — Get the Most from EWP

All-in-One Saw Solution

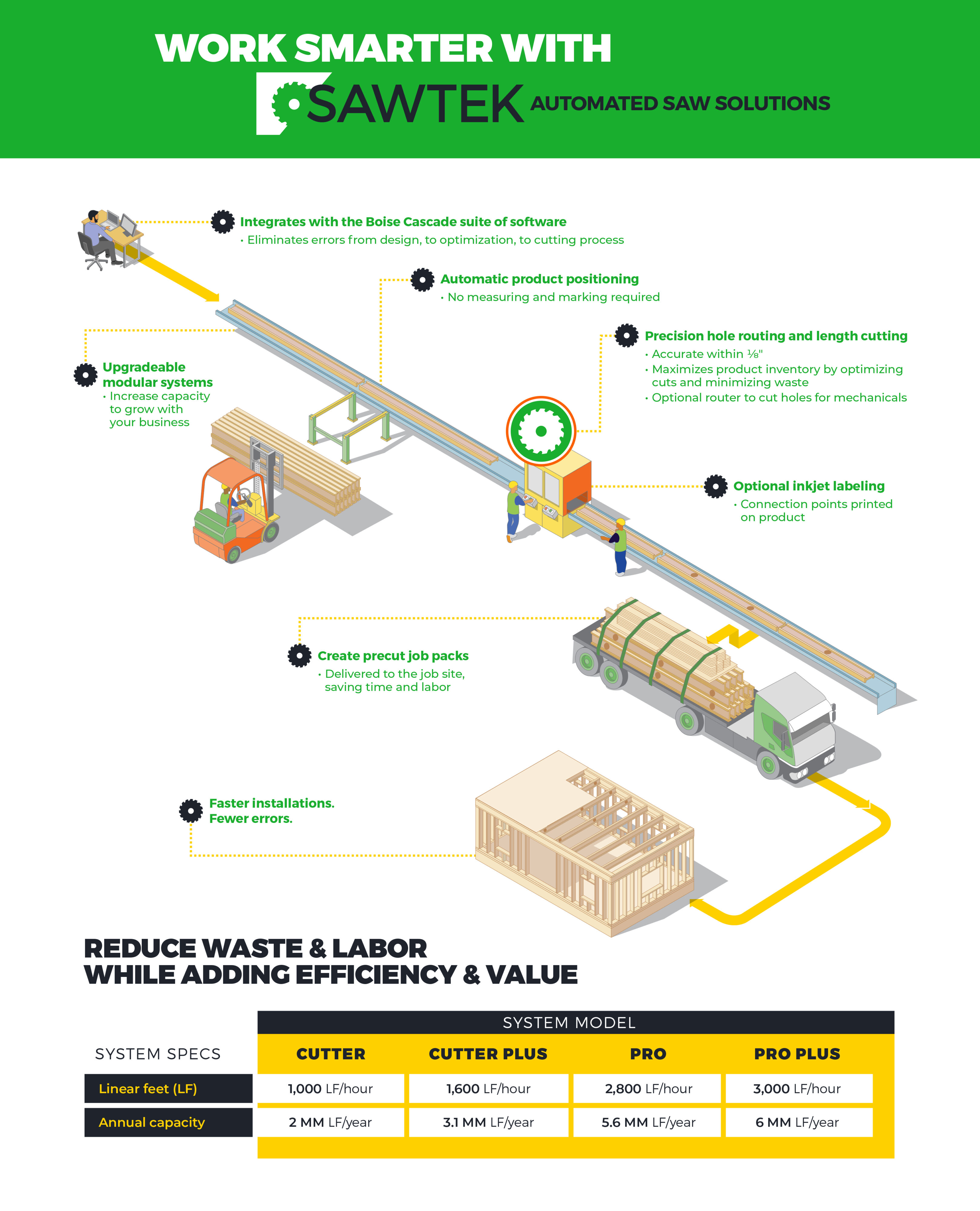

SawTek from Boise Cascade® combines software and hardware in an all-in-one saw system that automates your EWP processing and helps you extract every inch of profitability.

Reduces waste. Speeds production. And tracks all the details through a unified system to work smarter, not harder.

-

Optimize Inventory

Get more from your inventory.SawTek lets you reduce inventory levels, optimize lengths, stock fewer SKUs, and get more turns. All while reducing shrink by optimizing what you cut and when you cut it to ensure no material — or time — is wasted.

-

Simplify YourWorkflow

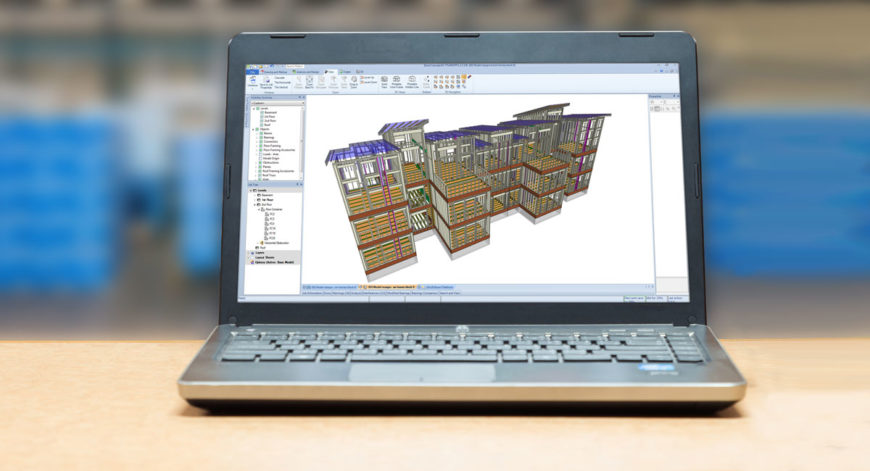

SawTek integrates with BC Connect® and BC Framer® to manage the entire process from a few design files. No more messy imports or lost paperwork. Eliminate manual data entry along with the missing pieces and other headaches it causes.

-

Buildto Suit

SawTek is available in multiple configurations and will adapt to your evolving business needs. We’ll work with you to design a system that fits your facility, traffic patterns, and production logistics — then help you maximize your investment by adding automation options as you grow.

The SawTek Process

From the desktop to the job site, SawTek makes framing a more predictable operation. EWP materials arrive on-site cut, packed, and labeled. No more confusion about which pieces go where. No more unnecessary cuts. No wasted time. Just a more efficient framing crew.

Faster in the Yard and on the Job Site

With production speeds up to 24,000 lineal feet a day, SawTek lets your team process at the lowest labor and dollar cost per foot possible.

For the job site, SawTek automatically cuts utility holes, then labels and organizes everything into framer-optimized job packs. Not only does this make it easier for them to find what they need when they need it, SawTek job packs reduce installation errors and improves framing crew efficiency.

Accurate to the Inch

SawTek’s computer-guided saw makes cuts within 1/8" of spec, making install easier for your customers and dramatically reducing waste for you.

Wasted inventory is the not-so-secret drain on profitability and a significant contributor to total package costs. With SawTek you can intermix cut lists of several jobs together for the best material utilization. This proprietary system lets you process cut packs without waste and manage off-cuts for returning usable lengths. Pieces can be optimized from one foot to whatever your customer desires. That’s efficiency and accuracy you’ll never get using traditional cut lists and chainsaws.

Builders — Work Smarter From Start to Finish

Take the Surprises Out of Framing

SawTek from Boise Cascade makes framing a more predictable operation. EWP materials arrive on-site cut, packed, and labeled. No more confusion about which pieces go where. No more unnecessary cuts. No wasted time. Just a more efficient framing crew.

From Home Plan

to Saw

Dealers who offer SawTek job packs use the latest technology to cut floor components directly from your plans. Design tools BC Connect and BC Framer feed into SawTek processing tools to produce job packs with only what you need and nothing you don't.

Get More Value from Your Lumber Yard

By choosing a lumberyard with the SawTek system, you benefit from their ability to calculate the optimum cutting strategy for your job, reducing potential waste, and maximizing your material.

-

Frame Faster

and SmarterPre-cut holes and clearly labeled components simplify workflow, allowing crews to work faster while significantly reducing the chance of costly errors.

-

Performance + Safety

SawTek's precision cuts, materials lists, and clear labeling virtually eliminate job site confusion, keeping your team working at speed with no compromise in quality or safety.

-

Efficiency by the Truckload

SawTek helps lumberyards more accurately forecast their inventory and use EWP more efficiently. For builders, it can mean shorter lead times and reduced construction timelines.

Sustainability Is Always On-Trend

Consumers are looking for more sustainable products in their homes these days, and Boise Cascade engineered wood fits right into that demand. Builders who use more sustainable and more efficiently produced framing materials send the right message. They’re actively part of the solution to reduce homebuilding’s impact on the environment.